Residual Torque Measurement

|

BMS Ireland

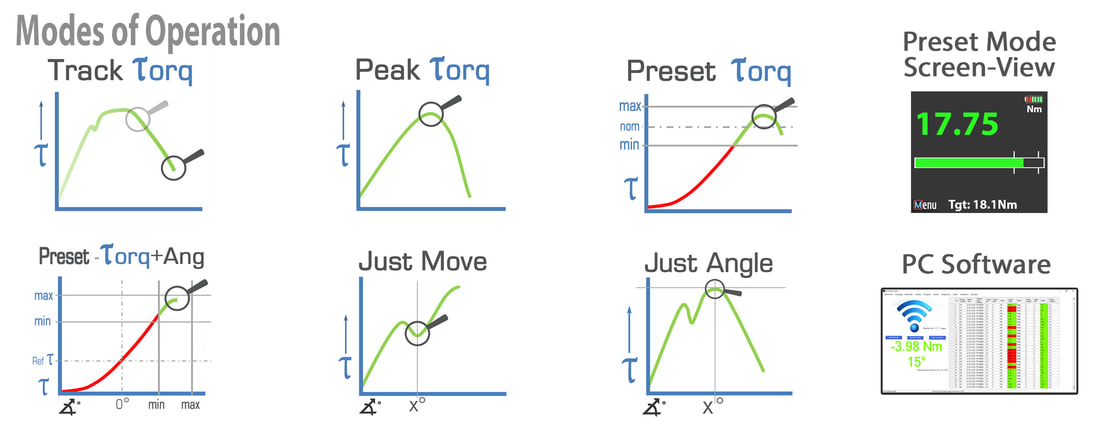

JUST MOVE FEATURE - TAW Series Captures the Torque at Selected Degree of Rotation For over 30 years BMS has Been an Industry leader in the design, development and manufacture of technology based Industrial Tools Key Features • Accuracy of ± 1% of Actual Reading from 10%-100% of full Scale

• Torque & Angle Modes available • Multiple Units (cNm, Nm, kgfm, kgfcm, ozins, lbins, lbft) • Multiple Languages (English, Chinese, French, German, Italian, Polish, Portuguese, Russian, Spanish) • Compatible with rechargeable or standard consumable batteries |

LightStarTM Residual Torque Measurement

ASI DATAMYTE’s LightStarTM system raises the quality bar by error-proofing residual torque, power tool optimization, hand assembly and rework operations. It eliminates the crippling downtime associated with reacting to false out-of-spec readings and the big costs associated with missing true defect conditions.

* U.S. Patent No. 7,934,428 EP Patent Application No. 08831666.6

LightStarTM torque and angle wrenches reduce variability in torque measurement. The LightStarTM system gives you the most reliable way to eliminate false readings and increase accuracy of residual torque measurement.

The time between fastener motion and operator response is a key driver of variability when measuring peak torque This is why assessing residual torque by measuring peak torque is subject to operator error that induces false high and false low readings, as well as much higher variability than measured installed torque.

A solid‐state gyro in the wrench captures torque only when the fastener actually turns. The data collector’s instrumentation differentiates between windup – the flexing of the work piece, drive, socket and extension – and actual fastener motion.

This system consists of:

ASI DATAMYTE’s LightStarTM system raises the quality bar by error-proofing residual torque, power tool optimization, hand assembly and rework operations. It eliminates the crippling downtime associated with reacting to false out-of-spec readings and the big costs associated with missing true defect conditions.

* U.S. Patent No. 7,934,428 EP Patent Application No. 08831666.6

LightStarTM torque and angle wrenches reduce variability in torque measurement. The LightStarTM system gives you the most reliable way to eliminate false readings and increase accuracy of residual torque measurement.

The time between fastener motion and operator response is a key driver of variability when measuring peak torque This is why assessing residual torque by measuring peak torque is subject to operator error that induces false high and false low readings, as well as much higher variability than measured installed torque.

A solid‐state gyro in the wrench captures torque only when the fastener actually turns. The data collector’s instrumentation differentiates between windup – the flexing of the work piece, drive, socket and extension – and actual fastener motion.

This system consists of:

- LightStarTM Torque Wrenches with angle measurement option

- Model 600 Data Collector with torque option

- TranSend II utility software

- Setup Editor and Reporting and Analysis Software